Design

your machine

Start with our modules and we will take care of the final machine…

On the left, select the module you are interested in, and then choose the most suitable technology.

For your needs in ultrasonic cutting and welding machines, either for the medical and personal protective industries or for the lingerie, please have a look at our standard welding and cutting machines.

Welding

Ultrasonic static welding

How to assemble without, any thread, or needle or glue or any added fabric, thermofusible materials and get an excellent resistance.

Winding and Ejection

Axial winding on core

Welding

Ultrasonic rotary welding

Thanks to the rotary process (wheel and horn are both rotating on parallel axis) the welding process is continuous at speeds from 0 to 350 m / min, depending on the applications.

Unwinding

Axial and/or tangential

Cutting

Continuous ultrasonic cutting

The ultrasonic cutting can be either a single cut to avoid any threading or a cut combined to a welding wheel to reinforce th cutting edge.

Winding and Ejection

Multiple winding

Simultaneous winding of different width cut products

(ex. from 3 to 100 mm on the same axis)

Manufacture and Integration

Automation

Programming from Siemens, Rockwell, Schneider Electric, Omron...

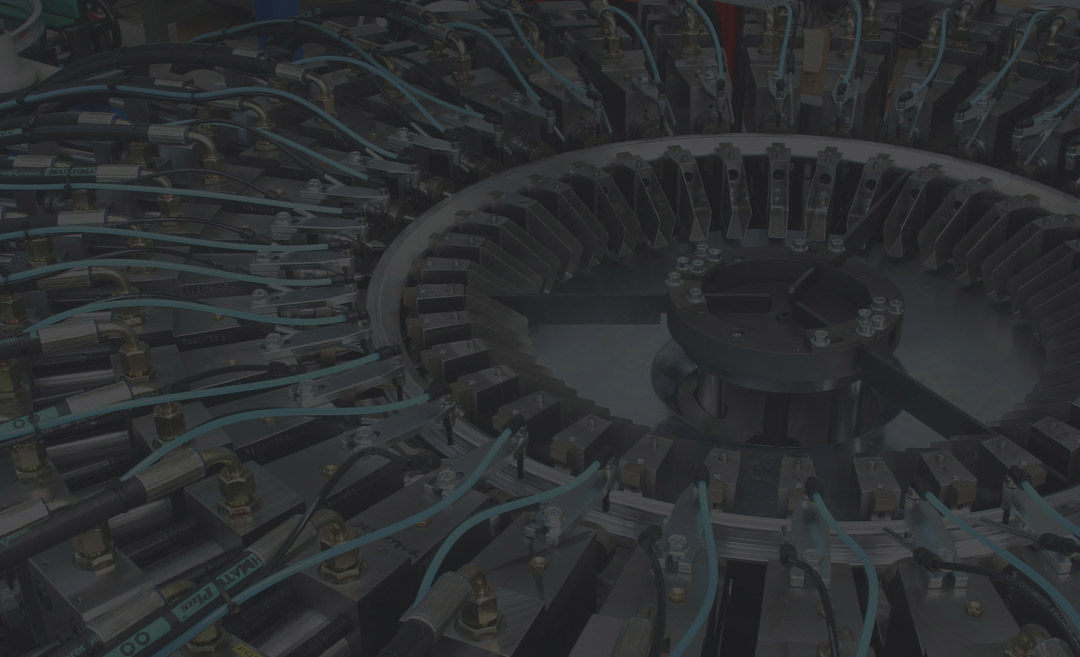

Welding

Ultrasonic welding on drum

A rotary welding drum with the welding pattern on combined to fix horns on a maxi width of 800 mm.

Transfer and Guiding

Transfer and manipulation

Angular rotation at a speed up to 50 m / min of “Light” products such as surgical masks, to re-orientate the product.

Know-how

Threading

Automatic threading of woven fabrics through a ring.

Unwinding

Wide width

Controlled unwinding tension

Width up to 3.20 m

Unwinding speed up to 100 m / min.

Know-how

Hot thermo moulding

A male and a female mould.

Technical or foam fabric moulding for any application even medical.

Welding

Heat cutting / welding and Impulse welding

Heat cutting / welding through blade or heating resistance.

Impulse welding through shaped heating blade.

Winding and Ejection

Horizontal pre-conditioning

Horizontal piling up of folded woven and non-woven products.

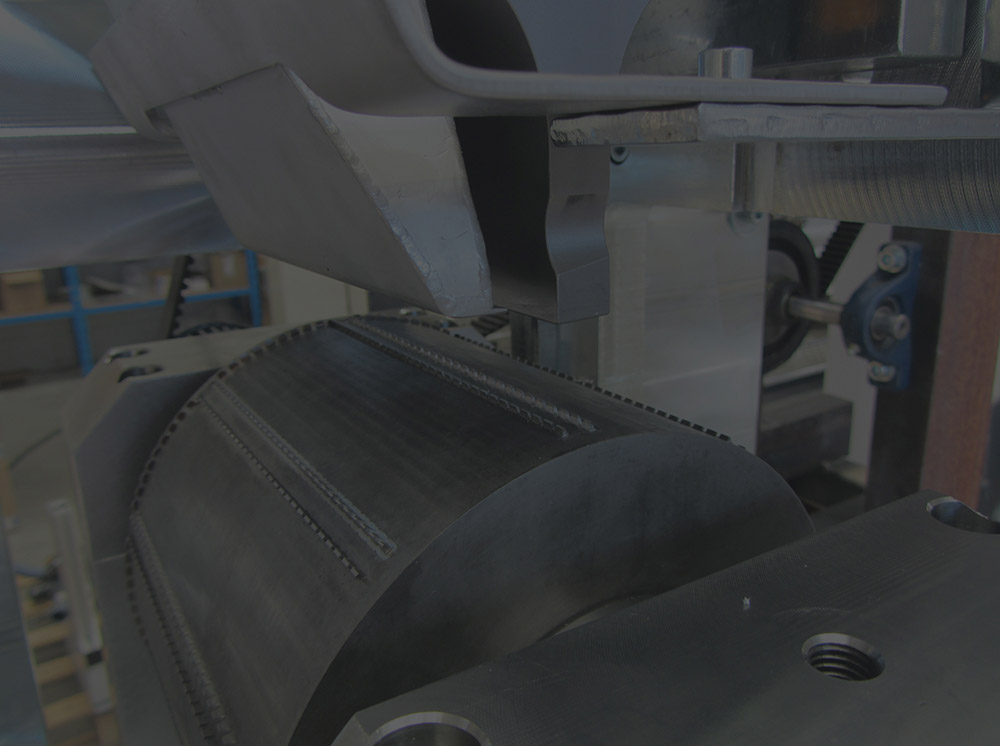

Cutting

Continuous mechanical rotary cutting

The continuous mechanical rotary cutting to get a straight cut at high speeds while the fabric is in movement (scissors cutting).

Transfer and Guiding

Transfer - Piling up

Belt transfer and piling up through pushing process.

Folding

Single folding

Folding frame with tension and positioning control.

Manufacture and Integration

Camera Control

Quality control through cameras and control PC for data collection :

- Positioning control

- Dimension control

- Defect control

Winding and Ejection

Vertical pre-conditioning

Vertical piling up of woven or non-woven products.

Welding

Cold sealing

Sealing through wheel and counter wheel.

Transfer and Guiding

Guiding frame

Web recentring all along the process.

Know-how

Samples / Tests

In our test lab, your products are tested and trials are made with the different ultrasonic powers to make sure we can answer your requests.

Folding

Multiple folding

Making of one or several folds in continuous from narrow or wide width.

Unwinding

Multi rolls

Simultaneous unwinding up to 6 rolls.

Control of the roll end with or without automatic splicing.

Manufacture and Integration

Mechanics

For more than 30 years our technicians have been assembling machines, and our specific unit manufactures the mechanical parts as per our specific needs...

Cutting

Mechanical cutting on drum

Rotary blade / counter blade to cut in shape during a continuous process.

Visiting address

2 rue du huit mai 1945

Visiting address

2 rue du huit mai 1945