Process

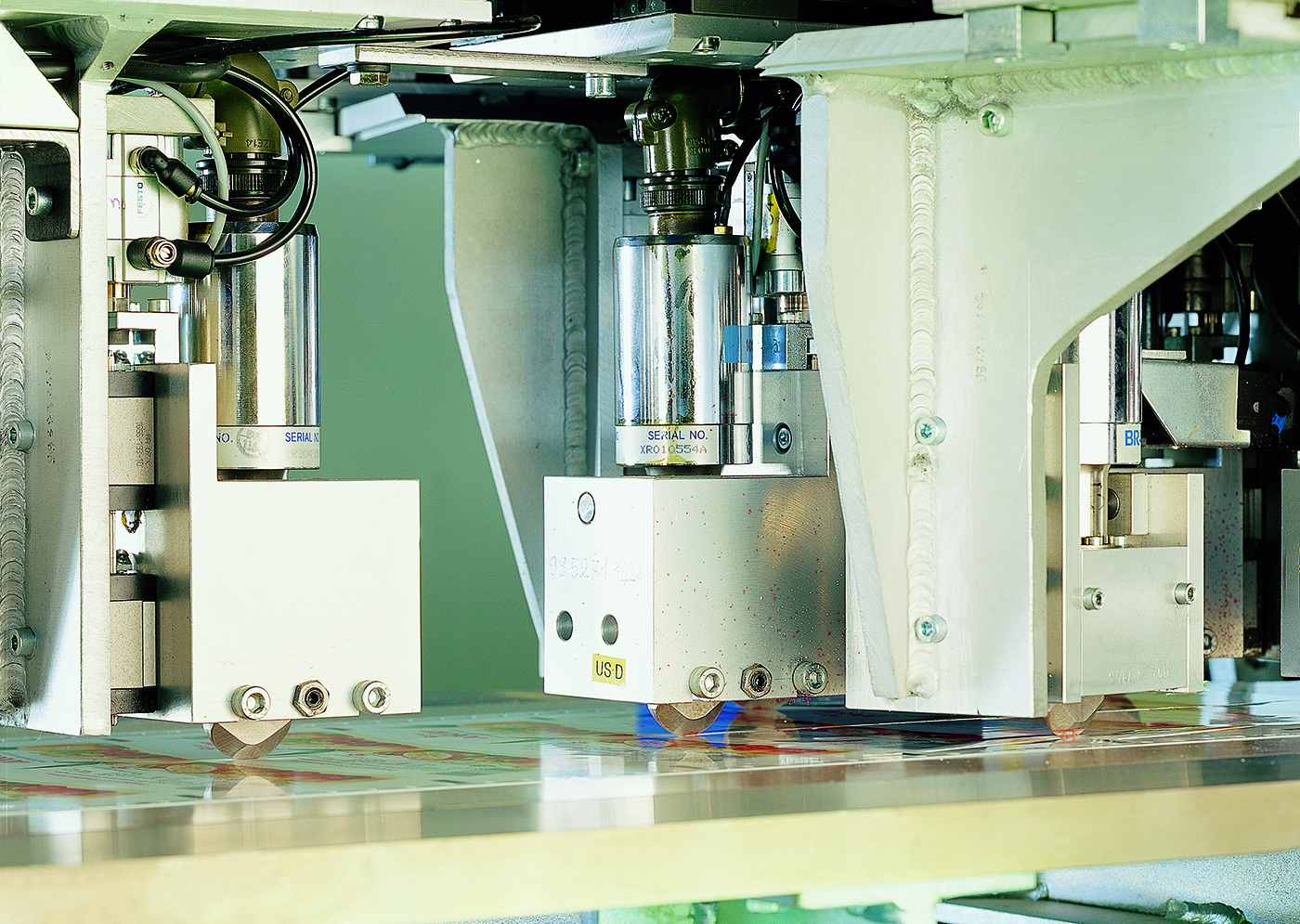

• Continuous or intermittent ultrasonic seaming of thermofusible fabrics (non-wovens, plastic webs, technical textiles …)

• Can easily replace a glueing station

• Its rotary process allows a constant sliding of the fabric avoiding any jamming

• Speed in production: up to 350 m/min

• Easy to integrate

Some applications

• Diapers: welding of the leg cuff

• Marking in continuous

• Continuous welding or cutting of several layers

• Seaming operations for the filtration industry

• Elastic welding …

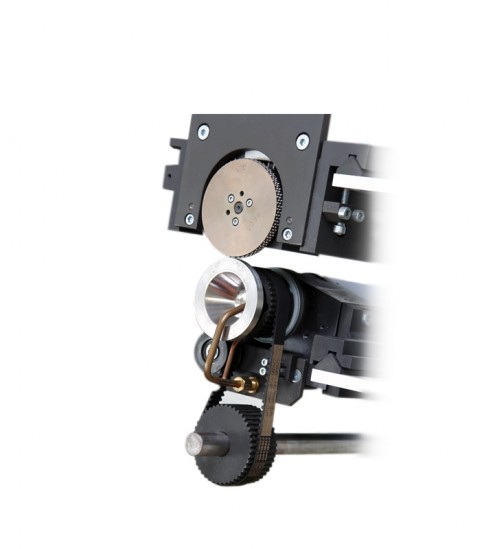

Technical features

• Sonics: 40 kHz, 700 W, Advanced generator

• Electrical tension: 220 V single phase, 50 or 60 Hz

• Pneumatic: 6 bar

• Overall machine dimensions:

– Dimensions (in m.): 0.57 x 0.28 x 0.38

– Weight: 26 kg

Why Cera Engineering ?

Because we combine years of experienced know-how in ultrasonic welding, with a technical expertise as a manufacturer of production machines. Industrial equipment at competitive prices. A wide range of cutting and welding tooling.

Other machines to ultrasonically cut and weld

Cera Engineering manufactures a range of ultrasonic welding machines dedicated to continuous and intermittent welding, cutting and marking of thermo-fusible fabrics.

CERA Ultrasonic machine – Ultrasonic machine to cut, weld and mark in continuous

CERA CR-US machine – Ultrasonic cutting machine, programmable to provide straight and inclined cutting of thermo-fusible fabrics

CERA 100 – Ultrasonic welding machine to provide stat../standards/machines-to-weld-and-or-cut-by-sonics/cera-ultrasonic-ultrasonic-sewinic welding and / or cutting